Our Story

At Saikou Wood, all materials are carefully inspected and responsibly harvested to give you and your family peace of mind when it comes to sustainability, durability, and air quality. The safest choice for your family.

With E0 formaldehyde emission, all our products consistently comply with CARB (California Air Resources Board) - the world’s strictest formaldehyde standard for wood products. We conduct laboratory testing every 3 months. E0 formaldehyde emission refers to the lowest level of formaldehyde release to indicate that a material is very safe for indoor air quality.

Why E0 Matters

•Health & Safety

Ultra-low formaldehyde levels help reduce the risk of respiratory problem, eye irritation, allergies, and

long-term health concerns especially for pregnant women, babies and children.

•Regulatory Compliance

Meets or exceeds formaldehyde emission standards in countries such as Japan, South Korea, China, and is

increasingly recognized in

the EU and US markets.

Certificates

From the raw material to the finished product:

discover the 6 steps of the whole manufacturing process

We exercise full oversight of our manufacturing process, from the initial raw materials to the final product. Each item that exits our facility undergoes a scrupulous manufacturing process, guaranteeing the utmost levels of quality and adherence to strict standards and guidelines.

-

The material

We source our wood from sustainable forests in Indonesia. Our wood is left untreated and undergoes meticulous quality checks before being transported to our factory.

-

Material Quality Checks

We bring it into our factory in Cirebon, West Java, Indonesia in the form of wooden logs. To ensure that our panel boards meet our rigorous quality standards, we conduct a thorough inspection of the wooden logs we use.

-

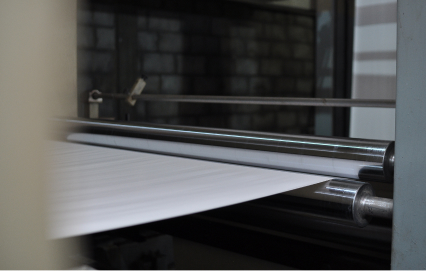

Production Process

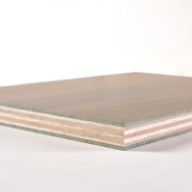

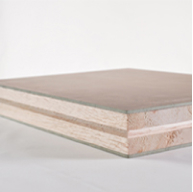

Once the wood has passed our rigorous quality checks, it is then processed into wood sheets to begin the production phase. Then the wood sheets are stacked and pressed using a 93.2-ton press per meter square, resulting in a very strong and durable quality product. Each wooden sheet has a barcode that is tracked throughout the production process.

-

Pattern and Texture Application

As part of our production process, we conduct a strict quality check to inspect each panel thoroughly before applying the desired color and texture patterns. With our extensive range of colors and textures, customers can easily find the perfect match for their project, streamlining the installation process and reducing overall costs.

-

Cutting and Edging

The final stage of the process involves cutting and edging the panel boards according to the specific requirements of each customer. These custom-cut boards can be used for a wide range of applications, including doors and cabinets, among others.

-

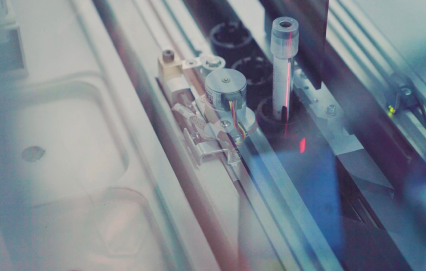

Lab Testing

To ensuring consistent quality, our products undergo lab testing every 3 months to consecutively fulfill CARB (The California Air Resources Board) the world's strictest formaldehyde emission standard for composite wood products.

Wood Product

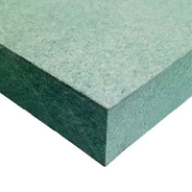

Types of Panel Board

Revamp Your Space with Our Wide Range of Colorful Panel Board Selections and textures

We have more than 40 colors available, in addition to the one shown on the website (with a minimum order of 50 pieces per color). All colors are applicable for all panel board, doors, and edging.